A ticking sound in your boiler could be due to air trapped in the system, expansion, and contraction of metal components during heating cycles, or pump issues.

If you’re unsure or concerned, it’s recommended to have a qualified technician inspect and address the specific cause.

A peculiar issue has emerged in the realm of home heating systems, one that resonates with an almost rhythmic regularity – the boiler ticking like a clock.

This distinct ticking demands attention in the often-overlooked symphony of household sounds, as it hints at potential underlying problems within the boiler system.

A boiler, akin to the heart of a home’s heating infrastructure, operates seamlessly when all its components harmonize.

Unusual sounds, such as the clock-like ticking, warn that something within this complex machinery might be amiss.

Ignoring or dismissing such noises could lead to problems ranging from decreased efficiency and increased energy consumption to potential breakdowns and safety hazards.

Understanding the Ticking Clock Noise

Description of the Ticking Sound

The ticking clock noise in boilers is often characterized by a rhythmic tapping or clicking sound resembling the ticking of a clock. This audible phenomenon can be disconcerting and may indicate underlying issues within the heating system.

Potential Reasons for the Ticking Noise in Boilers

Expansion and Contraction of Pipes:

- Description: As the boiler heats and cools during its normal operation, the metal pipes and components can undergo thermal expansion and contraction.

- Ticking Noise: The ticking sound may result from the expansion and contraction of pipes, particularly when they rub against support brackets or adjacent surfaces.

- Resolution: Installing pipe clips or insulation can help minimize friction and reduce the ticking noise caused by thermal expansion.

Air in the System:

- Description: Air trapped in the heating system can cause disruptive noises as it moves through the pipes or interferes with the flow of water.

- Ticking Noise: The ticking sound may occur when air bubbles are displaced or forced through narrow passages.

- Resolution: Bleeding the radiators and ensuring proper venting of the system helps remove trapped air, reducing or eliminating the ticking noise associated with air pockets.

Sediment Buildup in the Heat Exchanger:

- Description: Sediment, debris, or scale accumulation in the heat exchanger can impede the flow of water, affecting the boiler’s efficiency.

- Ticking Noise: The ticking sound may arise from the disturbance caused by water trying to pass through restricted pathways.

- Resolution: Regular maintenance can prevent or alleviate the ticking noise associated with heat exchanger blockages.

Other Potential Culprits

Water Hammer: Water hammer refers to the loud, hammer-like noises produced when rapidly moving water is suddenly halted or redirected within the plumbing system.

This phenomenon is often associated with the abrupt closing of valves or the sudden cessation of water flow.

- Role in Ticking Noises: A water hammer can create ticking or thudding sounds in a boiler system as the forceful stoppage of water flow results in pressure fluctuations that resonate through the pipes.

This can be particularly pronounced in older or inadequately supported piping systems.

- Solutions: Mitigating the water hammer can involve adjusting water pressure to more gradual changes, installing water hammer arrestors, or ensuring that valves close slowly rather than abruptly.

These measures help cushion the water’s momentum, reducing the likelihood of disruptive noises.

Limescale Buildup: Mechanism: The accumulation of limescale, a mineral deposit primarily composed of calcium carbonate, within the heat exchanger can lead to ticking or popping sounds.

As water passes through the heat exchanger, limescale deposits create uneven surfaces and hot spots, causing the water to boil unevenly and generate the associated noises.

- Importance of Maintenance: Regular maintenance, including descaling, is crucial for preventing limescale buildup.

- Descaling involves removing the accumulated deposits from the heat exchanger, ensuring optimal heat transfer, and preventing the development of disruptive sounds.

- Neglecting this maintenance task can result in decreased boiler efficiency and potential long-term damage.

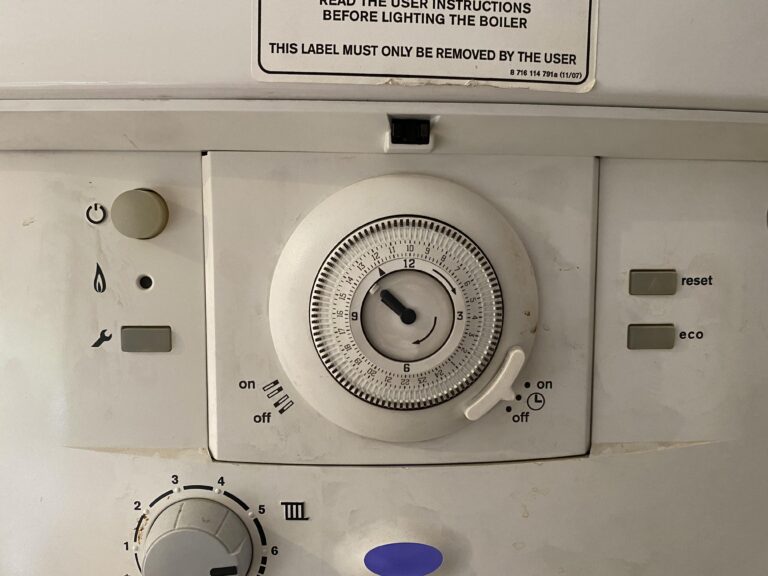

Thermostat Issues: Contribution to Sounds: Problems with the thermostat or its wiring can contribute to unusual boiler sounds.

If the thermostat is faulty or improperly wired, it may send incorrect signals to the boiler, causing erratic heating cycles or unnecessary activation of components, resulting in audible disturbances.

- Maintenance Advice: To address potential thermostat-related issues, homeowners should regularly check and ensure the thermostat is functioning correctly.

This includes verifying that the wiring is intact, the temperature readings are accurate, and the thermostat effectively communicates with the boiler.

Addressing thermostat-related issues can contribute to a quieter and more efficient heating system.

Assessing the Severity

Differentiating Normal Operational Sounds from Unusual Ticking

Normal Operational Sounds:

- Description: Boilers typically produce some level of noise during operation, such as the humming of the burner or the flow of water through pipes.

- Normal Ticking: Minimal ticking or clicking sounds during the initial heating phase or when pipes expand and contract due to temperature changes are considered within the normal range.

Unusual Ticking:

- Description: Unusual ticking sounds are those that deviate from the regular operational noise and may be more pronounced or rhythmic.

- Concerning Ticking: Ticking that is persistent, loud, or accompanies other abnormal symptoms warrants closer inspection.

When to Be Concerned About the Ticking Noise

Consistency and Intensity:

- Concerning Factors: If the ticking noise is consistent, intense, or increasing in frequency, it may indicate an issue that requires attention.

- Irregular Patterns: Ticking that follows irregular patterns or occurs when the boiler is not in operation may be a cause for concern.

Association with System Malfunctions:

- Concerning Indicators: If the ticking coincides with erratic boiler behavior, such as frequent cycling, uneven heating, or system shutdowns, it may signal an underlying problem.

Duration of Ticking:

- Concerning Duration: If the ticking persists for an extended period, especially after attempts to bleed air or address potential causes, it suggests a more serious issue that needs investigation.

Potential Implications of Left Unaddressed

- Reduced Efficiency:

Implication: Unaddressed ticking noises may be indicative of inefficiencies within the boiler, leading to reduced heating performance and increased energy consumption.

- Component Damage:

Implication: Continuous ticking could result in increased wear and tear on components, potentially leading to more significant damage over time.

- System Failures:

Implication: Ignoring ticking noises associated with malfunctions, such as air in the system or heat exchanger blockages, may contribute to system failures and costly repairs.

- Safety Concerns:

Implication: In some cases, ticking noises might be linked to safety issues, especially if they involve pressure fluctuations or irregular combustion patterns. Ignoring these concerns can compromise safety.

DIY Troubleshooting

Step-by-Step Guide to Identifying and Addressing Common Causes

Bleeding Radiators to Remove Air

- Turn off the Boiler: Ensure the boiler is turned off and has cooled down before starting the bleeding process.

- Prepare Tools: Have a radiator key, flat-blade screwdriver, and a cloth ready.

- Open Bleed Valve: Using the radiator key or screwdriver, slowly open the bleed valve at the top of each radiator. Listen for the hiss of escaping air.

- Collect Air/Water: Hold the cloth beneath the valve to catch any water or air escaping. Once the water starts flowing steadily without air, close the valve.

- Repeat if Necessary: Repeat the process for all radiators, starting from the lowest floor and working upward. This helps ensure that trapped air is released from the entire system.

- Check Pressure: Monitor the boiler pressure gauge and adjust it if necessary, following the manufacturer’s guidelines.

Checking for Loose Components

- Turn off the Boiler: Ensure the boiler is turned off and completely cooled down.

- Inspect Visible Components: Check for loose or visibly damaged components such as pipe brackets, clips, or connections. Tighten any loose fasteners.

- Listen for Ticking: Turn on the boiler and listen for the ticking noise. If it persists, try to identify the source by carefully listening to different areas around the boiler.

- Secure Loose Components: If loose components are identified, securely tighten or fasten them to eliminate potential sources of ticking.

Flushing the System to Remove Sediment

- Turn off the Boiler: Ensure the boiler is turned off and cooled down.

- Locate Drain Valve: Find the drain valve on the heating system. Attach a hose to the valve and place the other end in a suitable drainage area.

- Open Valve: Slowly open the drain valve to release water and sediment. Allow the system to drain completely.

- Flush with Fresh Water: Close the drain valve and refill the system with fresh water. Repeat the process until the drained water runs clear, indicating sediment removal.

- Bleed Air: After refilling, bleed air from the radiators to ensure the system is filled correctly.

Inspecting and Securing Pipework

- Turn off the Boiler: Always turn off the boiler before inspecting pipework.

- Visual Inspection: Examine the visible pipework for signs of movement, rubbing, or loose connections. Pay attention to areas where pipes may contact other surfaces.

- Secure or Adjust: Use appropriate clips or insulation to secure pipes and prevent friction-induced ticking. Adjust any misaligned or loose sections.

- Listen for Changes: Turn on the boiler and listen for any changes in the ticking noise. If the issue persists, consider seeking professional assistance.

Conclusion

Addressing the ticking sounds in a boiler is not merely about restoring peace to a home’s ambiance; it’s a proactive step toward ensuring the heating system’s longevity, efficiency, and safety.

From air pockets to water hammer, limescale buildup, and thermostat issues, understanding and promptly addressing these common culprits through regular maintenance and troubleshooting are key.

However, for more intricate problems, the involvement of a qualified professional becomes paramount.