Electrodes are essential components used to conduct electricity in various industrial applications. Because the layers of carbon atoms that make up graphite’s structure are held together by covalent bonds. High conductivity is made possible by its delocalized electrons, which are difficult to connect with atoms and make it an appealing choice for electrodes.

While electrodes can be made from different conductive materials still graphite stands out as a preferred choice because of its remarkable properties. Also, Noble metals like gold, silver, or platinum are costly on the other side copper, titanium, and brass also pose economic challenges.

Here, you will get to know a deeper understanding of Why are electrodes made of graphite besides the advantages of using it in industrial domains. Let’s get started

Why are electrodes made of graphite?

Layers of carbon atoms are organized in graphite, which retains its structure through bonds of covalent bonding. The abundance of delocalized electrons in the structure is a noteworthy characteristic. Only three of the outer energy electrons in graphite are required for bonding, leaving the fourth free to act delocalized.

Moreover, Electrons are free to move and are not easily linked to a specific atom. Although, it is widely used for electrodes because of its high conductivity, which is made possible by these electrons.

What are the main characteristics of graphite that make it useful for different purposes, especially as an electrode?

Electrical Conductivity: Because of its structure, graphite is a great electrical conductor due to carbon atoms form layers with delocalized electrons that may move freely, allowing for efficient electrical conduction.

Thermal Stability: It has high thermal stability, which makes it heat resistant and capable of withstanding extreme temperatures without major structural changes or deterioration.

Lubrication: Although low ratio of friction, makes it a good lubricant. In circumstances when standard fluid would be difficult or useless, it is frequently used as a dry lubricant.

Chemical Inertness: It is a fantastic solution for corrosive environments because it is chemically inert and has outstanding stability to most chemicals, acids, and bases.

Anisotropic Structure: anisotropic qualities due to its layered structure, which means that its physical properties differ dramatically in different directions. The layers’ exceptional thermal and electrical conductivity along their planes is caused by this diffraction.

High Strength-to-Weight RatioWeight to Strength Ratio: graphite has great strength and stiffness while remaining relatively lightweight, it is helpful in situations where both strength and weight are critical.

Low Thermal Expansion: When exposed to temperature variations, graphite doesn’t experience significant dimensional changes owing to its low thermal expansion factor.

As it cannot be wettable by most liquids, the material cannot absorb or hold moisture, making it perfect for use in humid or high-humidity conditions.

What are the Advantages of Using Graphite Electrodes?

Firstly, electrodes possess unique properties that make them highly valuable in various industrial applications. They exhibit high electrical conductivity, enabling efficient flow of electrical current.

Second, their high thermal adaptability allows them to stand up to extreme temperatures without degrading much. Because graphite is chemically inert, it is resistant to acids, bases, and dangerous conditions, ensuring long-term performance in electrochemical activities.

Furthermore, electrodes maintain structural soundness due to tiny reactions with other materials and a low thermal expansion ratio.

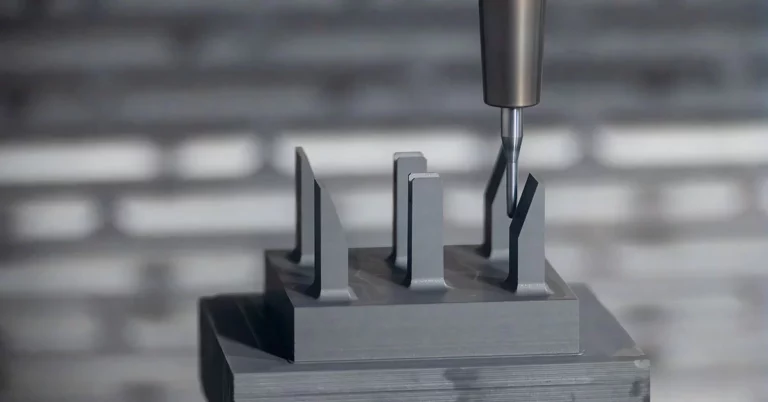

Finally, Because of its low cost, lightweight, and high strength-to-weight ratio, it is suitable for large-scale industrial use. The simplicity of machining allows for unique complicated electrode forms, contributing to its versatility in metals, electrochemical cells, batteries, and other applications.

What are some common applications where graphite electrodes are widely used?

Graphite electrodes have multiple uses across a variety of sectors due to their excellent conductivity and thermal stability, they have become commonplace in Electric Arc Furnaces (EAFs) for steel manufacturing.

Therefore, In electrolysis processes like aluminum smelting and copper refining, graphite electrodes act as anodes and cathodes, enabling desired chemical reactions.

Also, They are important components in rechargeable batteries and fuel cells, particularly in lithium-ion batteries where they serve as anode material for storing and releasing lithium ions. Electrochemical sensors, EDM operations, metal powder production, silicon, carbon material creation, graphene synthesis, water treatment, and plasma cutting all use graphite electrodes, demonstrating their adaptability and importance in a wide range of industrial applications.

Comparison with Other Electrode Materials

Graphite vs. Metal Electrodes:

- Graphite electrodes have higher electrical conductivity compared to most metals, except for noble metals like gold, silver, and platinum.

- Graphites are more affordable than other materials.

- Graphite stands apart from other metals by its exceptional resistance to heat and chemical inertness.

Graphite vs. Carbon-based Electrodes:

- Compared to carbon-based electrons, the heat of a graphite electrode is superior.

- While carbon-based electrodes can have a variety of patterns and factors graphite has a clearly defined layered structure.

- In general, graphite electrodes are more affordable than some specialist carbon-based electrodes.

- Even though, Graphite is used in various industries while carbon-based has specific applications like energy storage or advanced electronics.

FAQ

Are electrodes always made of graphite?

No, Electrodes can be made from various conductive materials like graphite, noble metals, copper, titanium, and brass.

What are the five uses of graphite?

- Writing Materials.

- Lubricants.

- Refractory.

- Nuclear Reactors.

- Batteries.

- Graphene Sheets.

Is graphite hard or soft?

Soft, Carbon atoms form graphite and diamond, with graphite being soft and slippery and diamond being the hardest.

Is graphite a metal?

No, Graphite is the only non-metal capable of conducting electricity, found on the right side of the periodic table.

Is graphite all carbon?

Yes, Of all the minerals, diamond and graphite are the most fascinating. Although they are vastly different physically, they are the same chemically since they are both made of carbon (C). Polymorphs are mineral forms with the same chemical but distinct crystal shapes.

Conclusion

As a result, graphite is used for electrodes with just three electrons for bonding, the fourth is free, enabling high conductivity and electrode suitability. Because of benefits like low cost, lightweight, and high strength-to-weight ratio, the industry utilizes it.

Even while they have limitations, continual improvements in manufacturing processes and materials portend a bright future. More effective and environmentally friendly electrode solutions will result from developments in nanotechnology and sustainable practices.